A Comprehensive Guide to Membrane Switch Design and Manufacturing

A Comprehensive Guide to Membrane Switch Design and Manufacturing

Blog Article

Understanding Membrane Switches: The Trick to Dependable and sturdy Controls

Membrane switches stand for an important aspect of modern user interface style, mixing functionality with resilience in numerous applications. As we discover the details of membrane buttons, it becomes clear that their function in enhancing control systems is both intricate and profound, elevating concerns about exactly how best to utilize their abilities in future technologies.

What Are Membrane Layer Buttons?

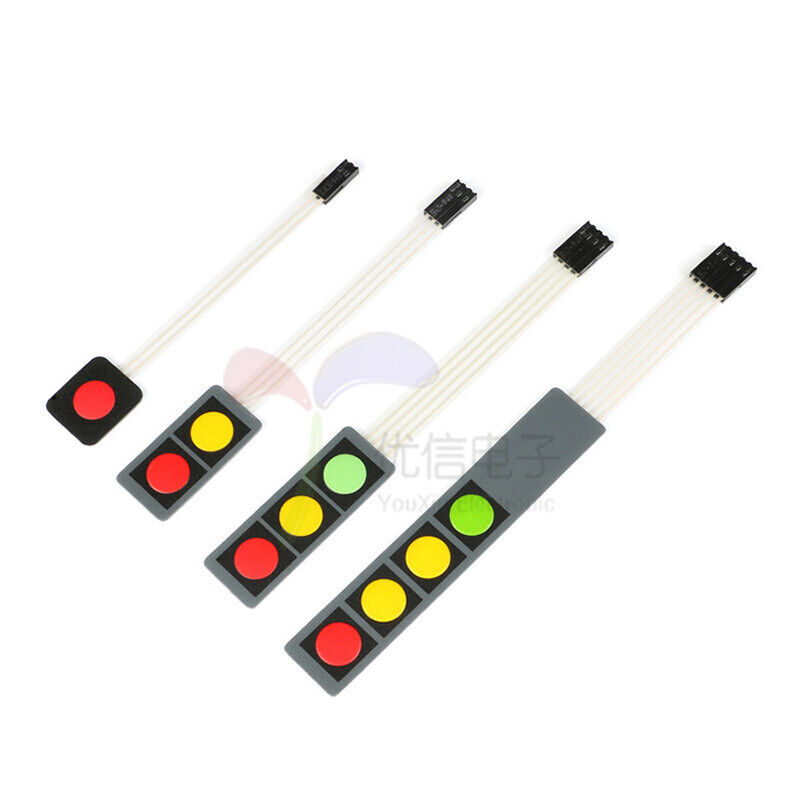

Membrane switches are an innovative remedy in the realm of interface modern technology, incorporating capability and layout flawlessly. These devices offer as an interface in between customers and electronic systems, integrating several parts right into a small format. Generally created from adaptable, slim layers of products, membrane layer buttons are developed to react to touch, enabling customers to interact with equipment and electronic devices successfully.

The primary aspects of a membrane button include a published circuit layer, visuals overlay, and a spacer layer that stops unplanned activation. The visuals overlay can be tailored to mirror brand name identification or individual choices, enhancing visual appeals while making sure use. Membrane switches are frequently utilized in various applications, consisting of medical gadgets, customer electronics, and commercial devices, owing to their longevity and resistance to environmental elements such as wetness and dust.

Among the essential benefits of membrane layer buttons is their ability to hold up against wear and tear, making them excellent for high-traffic settings. In addition, they are light-weight and call for marginal space, permitting ingenious styles in product development. Overall, membrane layer switches over stand for a useful and effective selection for contemporary electronic interfaces, weding modern technology with user-centric design principles.

How Membrane Changes Work

The operation of membrane switches over rest on a simple yet effective mechanism that translates individual input into electronic signals. These buttons are composed of multiple layers, normally including a visuals overlay, a spacer layer, and a circuit layer. When a customer presses the button, the leading layer deforms, allowing a conductive component in the circuit layer to make call with an equivalent conductive pad on the underside of the visuals overlay. This contact shuts the circuit and sends out a digital signal to the gadget, suggesting that the switch has been triggered.

The style of membrane layer switches can vary, however they typically include domes or responsive components to give comments to the customer, enhancing the total experience. The materials utilized in membrane switches, such as polyester or polycarbonate, add to their toughness and resistance to environmental variables, consisting of moisture and dirt. The published circuits are generally enveloped, which safeguards them from wear and tear over time.

Advantages of Membrane Layer Switches

One of the main benefits of membrane layer switches is their versatility in style, permitting them to be customized to satisfy specific user demands and visual requirements. This versatility expands to different industries, where different forms, sizes, and colors can be employed to boost customer interaction and visual charm.

Furthermore, membrane buttons are understood for their sturdiness. Created from robust materials, they are resistant to dirt, wetness, and physical wear, which significantly expands their lifespan compared to typical mechanical buttons. This toughness makes them especially appropriate for high-traffic atmospheres and applications requiring longevity.

In addition, membrane layer buttons offer a structured profile, bring about a thinner layout that can be integrated into different tools without adding mass. This attribute not just enhances the visual charm yet also adds to a much more ergonomic product style.

Applications of Membrane Layer Buttons

Flexible and user-friendly, membrane layer switches discover applications throughout a large array of industries, including clinical devices, consumer electronics, and commercial devices. In the medical field, these switches are important to devices such as diagnostic tools, patient tracking systems, and mixture pumps, where dependability and ease of cleaning are essential. Their capability to hold up against harsh environments and keep functionality makes them suitable for such applications.

In consumer electronics, membrane switches are made use of in products like microwaves, cleaning devices, and remotes - membrane switch. Their sleek style allows for intuitive customer interfaces, boosting the general user experience while providing toughness and go to these guys resistance to tear and put on

Commercial tools likewise gains from membrane layer buttons, particularly in control panels for equipment and automation systems. These buttons offer protection against dirt and dampness, guaranteeing regular performance in challenging settings. Their adjustable features allow suppliers to customize them to specific operational requirements, improving effectiveness and capability.

Choosing the Right Membrane Layer Change

When selecting a membrane switch, it is necessary to consider different factors that influence performance and suitability for specific applications. The primary considerations consist of environmental conditions, tactile comments, toughness, and design requirements.

First, evaluate the operating atmosphere; buttons revealed to dampness, chemicals, or severe temperatures need details materials to guarantee longevity and performance. Next off, assess the demand for tactile responses. Depending upon individual communication, some applications may take advantage of a tactile response to confirm activation, while others may prefer a non-tactile design for aesthetic factors.

Durability is an additional vital element; membrane buttons should be designed to stand up to regular use, impacts, and abrasion. Guarantee the selected switch can withstand the expected lifecycle, particularly in high-usage scenarios.

Conclusion

Finally, membrane switches over act as essential parts in the design of trusted and resilient control systems across numerous industries. Their portable layout, integrated with robust construction and adjustable attributes, boosts customer communication while making certain durability sought after settings. The versatility of membrane switches permits customized remedies that fulfill particular functional needs, reinforcing their relevance in contemporary innovation. membrane switch. As markets remain to progress, the check it out importance of integrating effective membrane button solutions can not be overemphasized.

Membrane switches stand for a crucial facet of modern interface style, mixing performance with resilience in numerous applications.Membrane switches are a sophisticated remedy in the world of individual interface innovation, combining capability and design perfectly. Typically created from flexible, thin layers of materials, membrane switches are made to react to touch, allowing customers to communicate with equipment and electronic devices effectively.

The style of membrane buttons can differ, however they commonly incorporate domes or tactile components to offer responses to the customer, enhancing the overall experience.In conclusion, membrane changes serve as important elements in the style of reputable and long lasting control systems across different industries.

Report this page